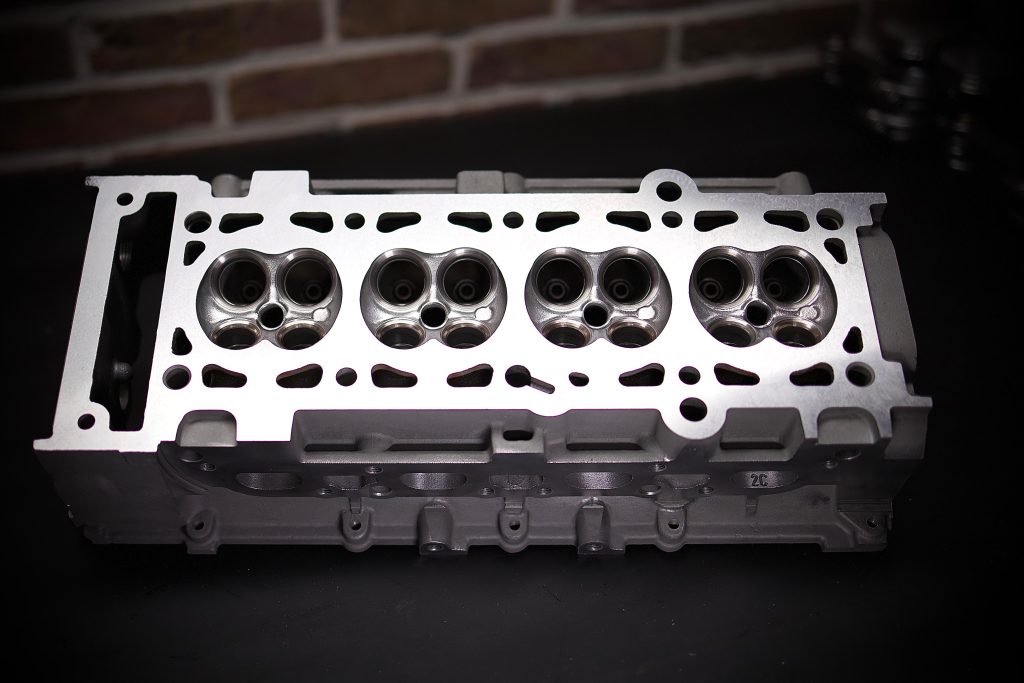

Cylinder heads

VALVE JOB

Valve seats are one of the most critical components of any cylinder head. That’s why every cylinder head we build receives a carefully tailored, high-precision valve job, specific to the engine type and application.

Improved sealing for better compression

Valve seats provide the sealing surface that the valves close against. A poor seal can lead to compression loss, misfires, and reduced performance. With our precision-machined valve seats, we ensure a perfect fit between valve and seat.

Cooler-running valves for longer life

Valve seats aren’t just about sealing, they also play a crucial role in cooling. As the valve closes, it transfers heat into the seat, which then dissipates it into the cylinder head. Poor seat-to-valve contact results in excessive heat buildup, leading to burned valves or premature wear. Our process guarantees optimal thermal contact, improving durability and extending the service life of the valve train.

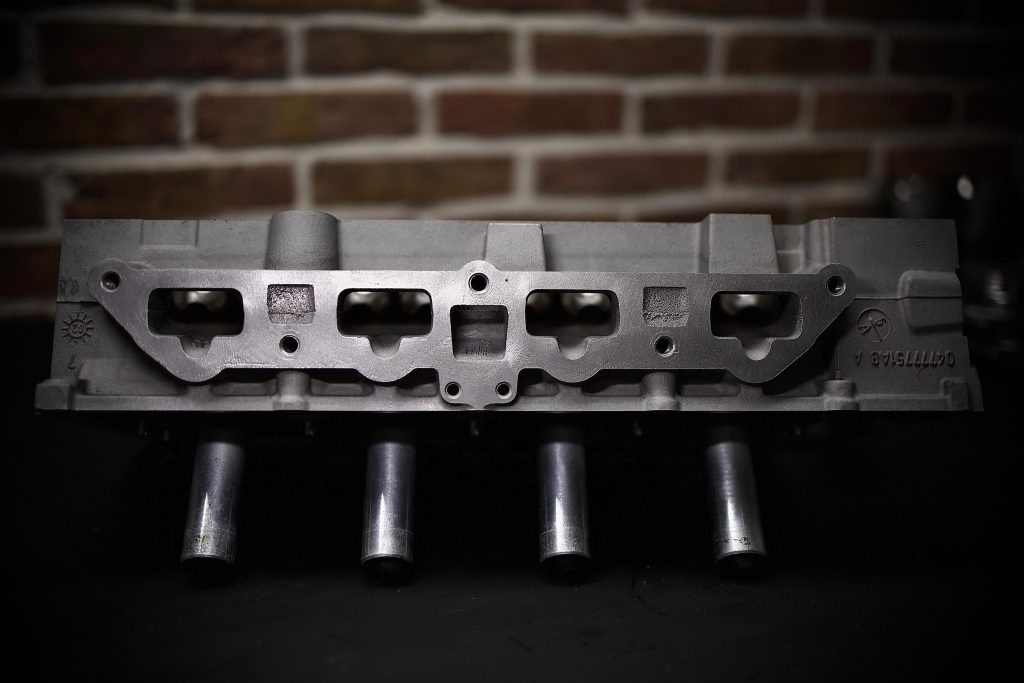

Enhanced airflow for better performance

The angles and contours we machine into the valve seats significantly affect how air enters the cylinder. These flow characteristics determine how efficiently the engine breathes at different RPM and valve lifts. By using optimized multi-angle seat profiles, we reduce flow restriction and improve overall cylinder filling, resulting in more power and better throttle response compared to stock heads.

RESURFACED

We resurface every cylinder head before it leaves our shop, no exceptions. This process is essential to ensure that the sealing surface is perfectly flat, true, and has the correct surface finish for modern multi-layer steel (MLS) or composite head gaskets.

Proper surface preparation is critical for head gasket performance. The gasket must seal the combustion chamber as well as oil and coolant passages under extreme pressures and temperatures. Even minor surface distortion, warpage, or incorrect roughness can compromise the seal, leading to gasket failure, overheating, or oil/coolant leakage.

By resurfacing each cylinder head to strict tolerances and the correct surface finish, we maximize sealing conditions, reduce the risk of failure, and ensure long-term engine reliability.

CASTING

Each cylinder head begins with an OEM-grade casting that is carefully selected and verified before any machining starts. Every casting is visually inspected for structural defects, surface flaws, or irregularities that could compromise strength.

We then perform a pressure test to detect internal cracks, porosity, or weak spots that may not be visible externally. This step ensures that the casting can reliably withstand combustion pressures, thermal cycling, and mechanical stress under real-world and racing conditions.

All threaded holes are inspected for wear, deformation, or damage to ensure proper torque retention during assembly. Only castings that pass all tests and meet our internal tolerances are approved for use in our engine builds.

This guarantees a solid, defect-free foundation for every high-performance cylinder head we deliver.

Fast & valuable support

We promise to reply to your email as soon as possible, with a clear and valuable response.

Tailored engine solutions

We promise expert advice to ensure you get the right components and services for your engine.

Know before you pay

We always inform you about product availability before you pay, so you won’t face unexpected delays.